Automated Order Picking Systems

In most warehouses and distribution centers, order picking is one of the most labor-intensive and time-consuming processes. However, by developing more streamlined systems, employing more intelligent warehouse automation and execution software and integrating innovative technology, we can completely transform one's operation.

The engineers at MMCI will take the time to learn your business's unique needs. We will work closely with you to create and implement the perfect automated picking system that will reduce labor costs, increase accuracy, and fit your business's products and budget. Explore some of the more common automated picking systems we utilize, and contact us today.

Goods-to-Person Systems

Hai Robotics helps us create these game changing solutions by designing flexible, highly efficient automated order picking solutions that will keep your operations functioning ahead of the industry for years to come.

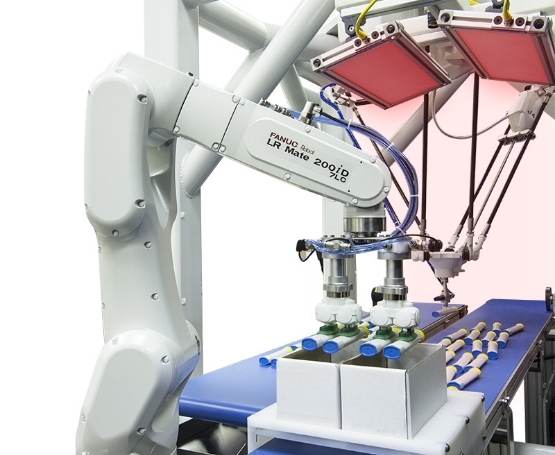

Robotic Order Picking

While robotic order picking is still in its infancy, we are able to leverage our extensive knowledge and experience in automating warehouses and distribution centers with our comprehensive capabilities in robotic automation to solve all types of order picking challenges.

A-Frame Picking Systems

A-Frame picking systems combine elements of storage, automated picking and conveying in one self-contained automated machine designed to process a high volume of orders at a very low cost.

Pick-to-Light Systems

Pick-to-light systems are one of the most productive order fulfillment solutions - increasing productivity and accuracy while reducing costs throughout all the stages of the order filling process. The technology has a very low learning curve so productivity gains are quick, even with new and seasonal employees.

Pick-to-Voice Systems

Voice picking systems are a very user-friendly and easy-to-learn technology that has successfully increased productivity, accuracy and safety in many operations. These systems' primary benefit is that they allow order pickers to have their hands and eyes free at all times.

Put-to-Light Systems

Put-to-light systems or "put walls" are typically deployed in operations that utilize batch picking processes. They use the same technology as pick-to-light systems, but with a reverse process flow - deconsolidating batches of into their respective orders.

Smart Order Picking Carts

By integrating iPads with industry-standard warehouse carts, our team has developed very cost-effective smart order picking carts that work in conjunction with our DCX Software suite to completely streamline the order picking process.