Our Work

Robotic Palletizer Case Studies

"We have a talented team of passionate engineers and problem solvers that think outside of the box to out-smart and out-design our competition to provide the best solution for our clients."

— Eric Kirkman, General Manager

Molded Fiber Egg CartonsPalletizing Extra Tall Pallets

Process Automated:

- Bundle Palletizing

- Bundle Labeling

Packaged FoodA "World Class" Palletizing System

Processes Automated:

- Palletizing

- Quality Control

- Data Capture

Consumer Packaged GoodsPalletizing Cases of Wine

Processes Automated:

- Case Palletizing

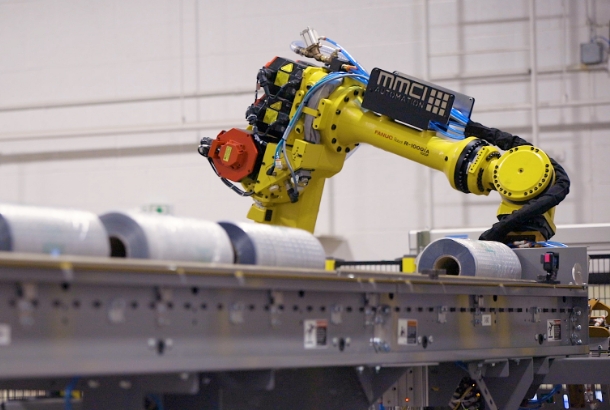

Heavy RollsInnovative Roll Handling

Processes Automated:

- Case Packing

- Palletizing

- Data Capture

Paper BundlesStrapping & Packing

Processes Automated:

- Strapping Bundles

- Palletizing

Metal IngotsA Heavy-Duty Solution

Processes Automated:

- Unitizing

- Banding

Pressure Sensitive PouchesHandling Fragile Items

Processes Automated:

- Tote Packing

- Palletizing

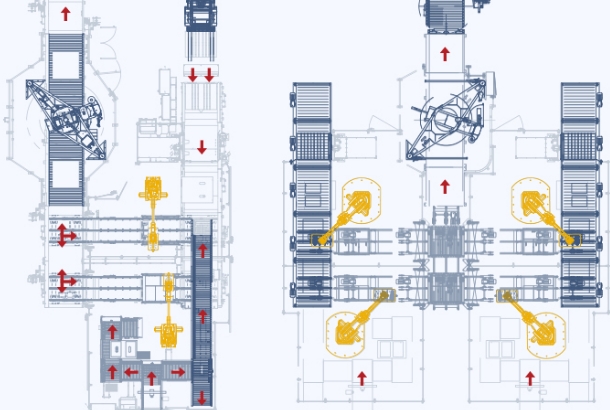

Packaged GoodsUpstream Innovation

Processes Automated:

- Case Palletizing

Frozen Food PackagesPalletizing in Freezing Temps

Processes Automated:

- Case Palletizing

Frozen Food PackagesIce Bag Palletizer

Processes Automated:

- Bag Palletizing

Building MaterialsVision Guided Unitizing

Processes Automated:

- Sorting

- Unitizing

ElectronicsComplex Cubing & Palletizing

Processes Automated:

- Cubing

- Palletizing

Paperboard ContainersAutomated Packing & Palletizing

Processes Automated:

- Case Packing

- Case Sealing

- Palletizing

Consumer Packaged GoodsSmall Footprint Palletizer

Processes Automated:

- Case Palletizing