Common Palletizer Enhancements

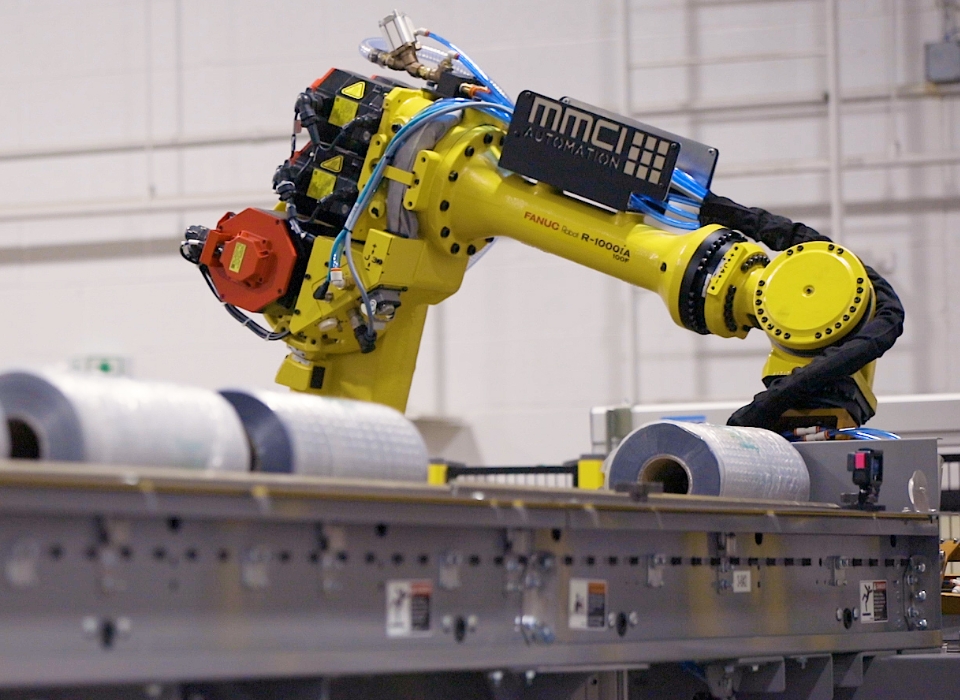

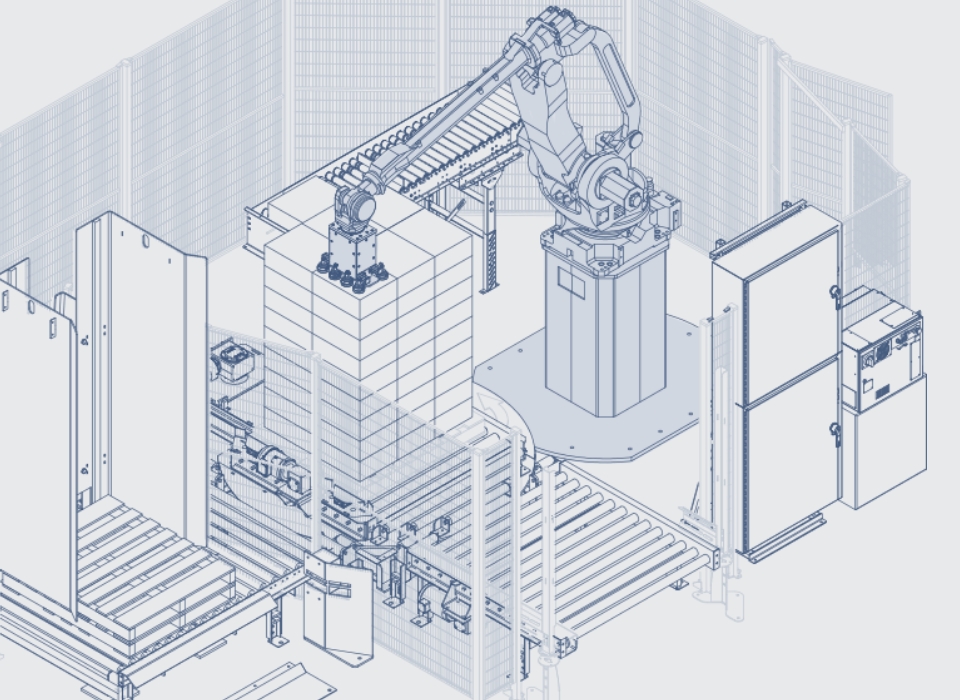

Given our extensive experience and modular approach to developing robotic palletizers, we often integrate additional features and automation into our QSP line of palletizers in quick and cost-effective manner to meet the specific needs of our clients.

Customized "Standard" Palletizers

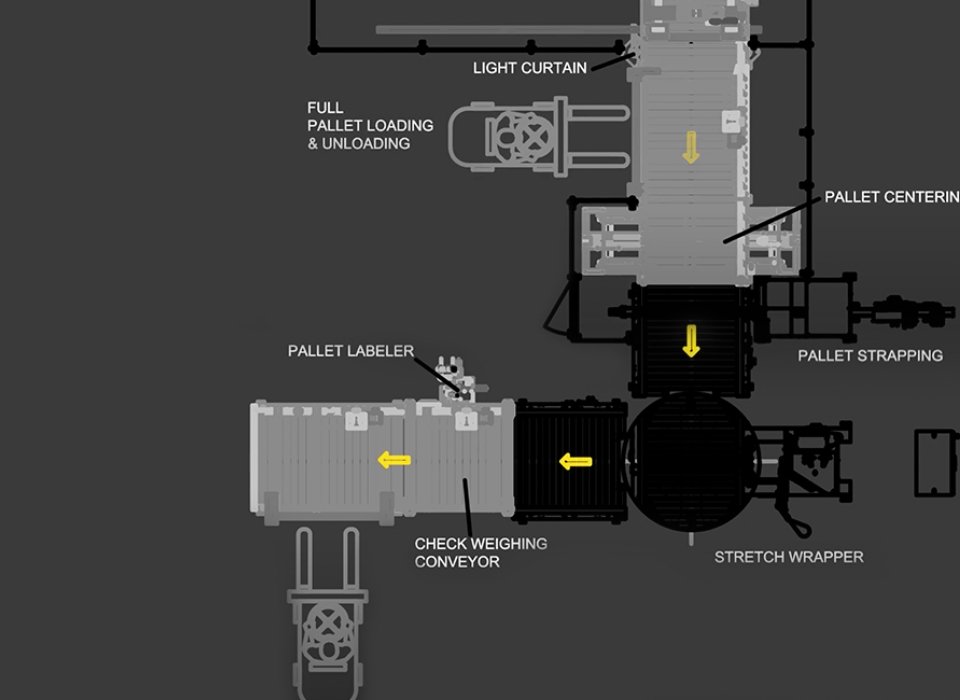

From basic enhancements to increase the speed of the palletizer to integrating complete upstream and downstream systems, our use of pre-engineered systems and controls still render most systems as "Standard Palletizers" even though they are completely customized to your needs.

Examples

- Enhanced Speed

- Upstream Process Automation

- Downstream Process Automation

- Custom Configurations or Footprints

- Integrated Quality Control or Tracking

- Special Requirements - Temperature, Chemicals, etc.

Customization

While our Quick-Ship Robotic Palletizers feature a standard conveying solution for bringing products into the cell, our team will often apply intelligent engineering, smart technology or highly customized options to meet the specific needs of our customers.