Our Process

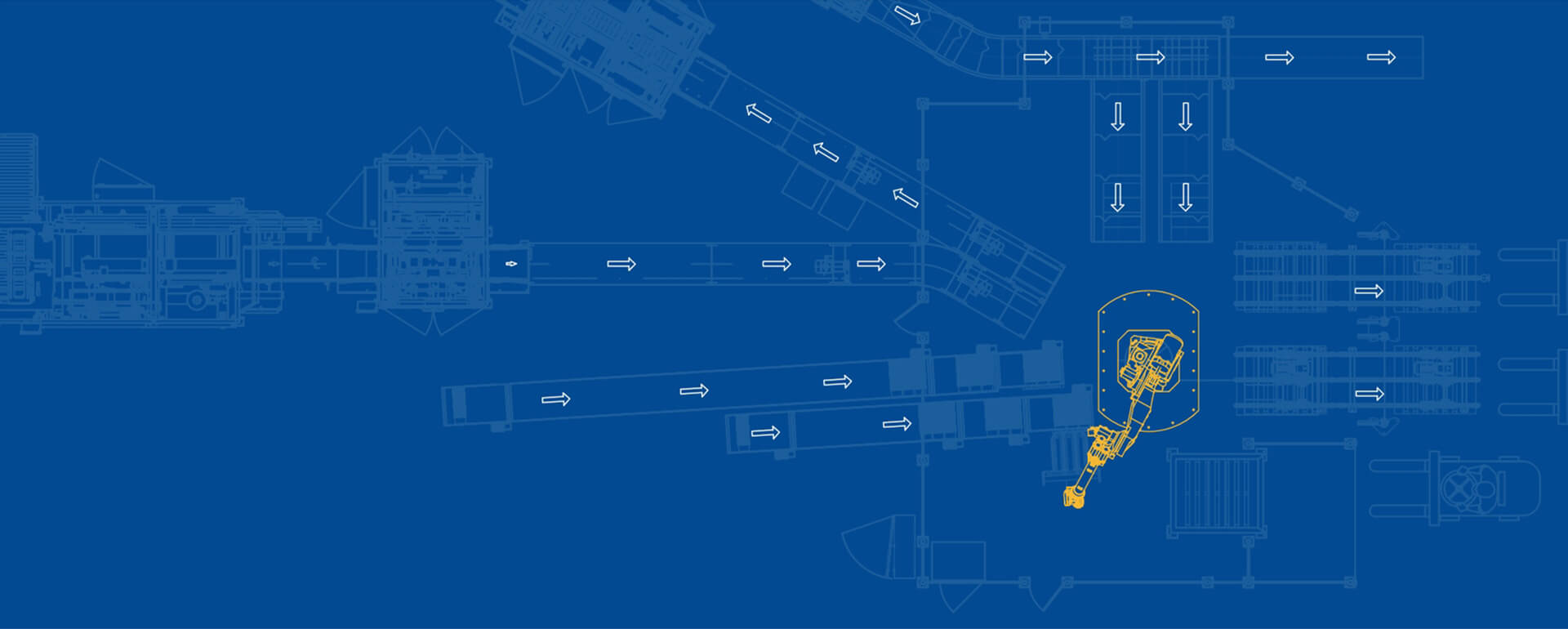

At MMCI, we help you select the best robotic palletizing technology for your application and then unleash our in-house design and controls teams to develop, integrate and deploy a system that will take your automation to a new level.

Step 1Evaluate Your Operation

Specifying the right palletizing technology starts with gaining a thorough understanding of your operation:

Production Line Speed

Pallet Configurations

Upstream Processes

Downstream Process

Available Space

Special Requirements

Step 2Specify the Technology

After evaluating your operation and any specific requirements, we can help determine the best palletizing technology for your operation.

Quick-Ship Palletizers

Quick-Ship Palletizers

Cost-effective, pre-engineered palletizers that ship quickly, install easily and run efficiently.

Collaborative Palletizers

"Quick-Ship" palletizers with enhanced automation or minor customization.

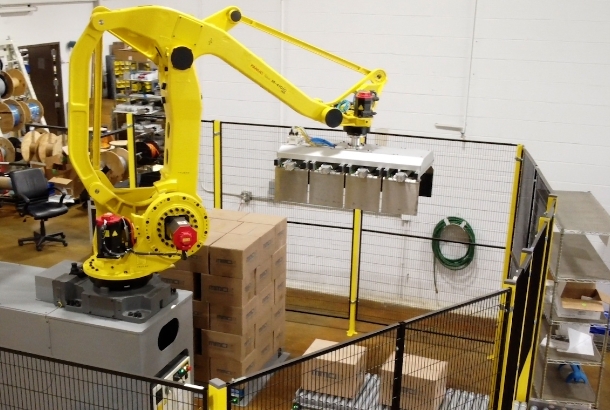

Customized Palletizers

Customized palletizing solutions for atypical products, enhanced automation or other special applications.

Step 3Design the System and Controls

Whether we specify an off-the-shelf palletizer or engineer a customized solution, our in-house controls team will develop all systems needed to integrate the automated palletizing system into your operation.

Step 4Test and Deploy

We design and build all robotic palletizer systems in our centrally-located tech center in St. Louis, Missouri. There, each unit is tested and validated before being integrated into your facility.