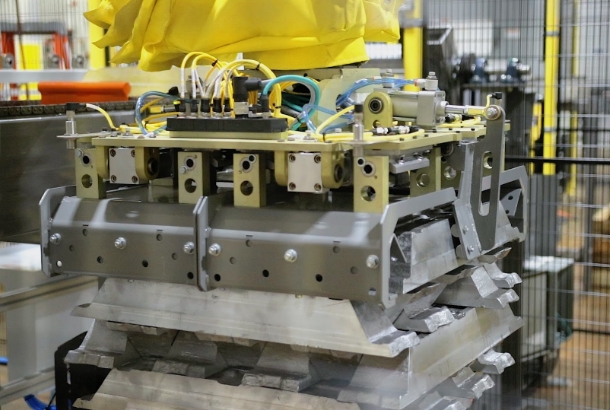

Ingot Palletizing

Palletizing or unitizing metal ingots can be a challenging task due to the heavy weights of the product, high temperatures and special banding and stacking requirements. However, our engineering team rarely backs down from a challenge.

Key Benefits

Using our extensive experience, our in-house design, robotics and controls teams can engineers your entire ingot robotic palletizing system to make it Safer, Faster, Smarter and More Cost-Effective.

Safer

By automating the entire process from aligning ingots for stacking to binding unitized loads, we can effectively eliminate your workers exposure to the heavy lifting of the hot, metal ingots.

Faster

Through the use of inline sensors and controls we develop automated systems for each function to ensure maximum productivity.

Smarter

By using inline scales that calculate the exact weight of each unitized load and output a label, our clients get the information they need quickly and accurately.

More Cost-Effective

In addition to the inherent cost benefits of automating, our team used rugged conveyors and intelligent controls to reduce workload on the robot and maximize long-term ROI.

A Case in Point

See how we accomplished all of these goals for a major recycler of aluminum for the auto industry.