Palletizing Safety

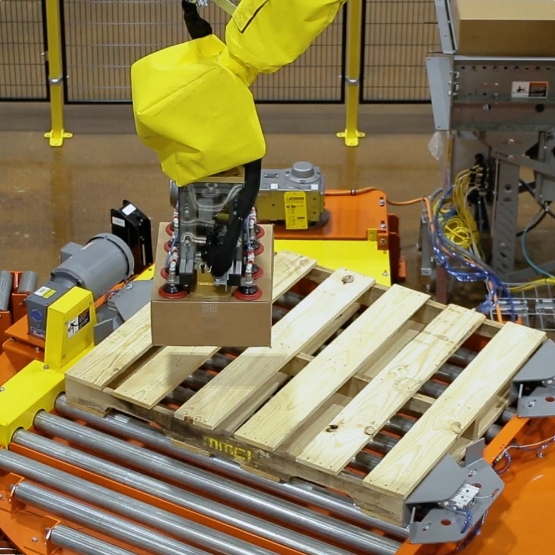

There is little debate that robotic palletizing systems make most operations inherently safer by eliminating physically demanding, manual processes that require a lot of heavy lifting, but here is how MMCI goes further.

7 Steps to Safer Palletizing

MMCI Robotics builds systems with safety in mind - to meet or exceed ANSI and OSHA standards for worker safety.

Intuitive Controls

Intuitively-designed HMIs allow operators to monitor and control every aspect of the system from a safe area outside the cell.

Safety Equipment

Designs typically feature emergency robot braking as well as audible and visual warning signs.

Easy to Operate

All systems are designed with a focus on ease of operation to ensure added safety.

Safe Conveyors

Cells are often outfitted with 24-volt infeed conveyors that are safer for workers hands and fingers.

Power Systems

Systems typically feature safety-programmable controllers that reside in a single controller chassis.

Access Control

Cells are not only outfitted with barriers, sensors and more, but they can be safely run from outside the cell.

Proper Installation & Training

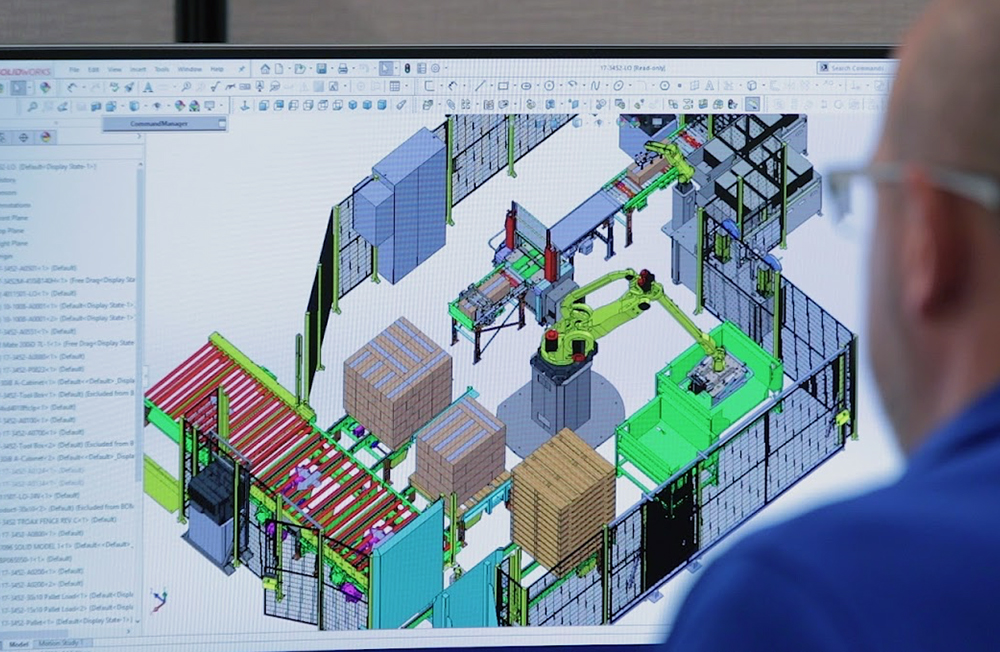

Systems are built and tested prior to deployment, installation and onsite training.

Safeguarding and Training

An effective safety system protects operators, engineers, programmers, maintenance personnel, and others who could be exposed to hazards associated with a robot's operation. A combination of methods may be used to develop an effective safety system.

A Case in PointFrozen Food Palletizing

Like many meat and frozen food processors, MMCI's client, one of the largest raw food producers in North America, wanted to eliminate the amount of human exposure to the freezing temperatures of the palletizing area while increasing productivity. The solution needed to fit within a very limited space in the facility and be delivered and installed with minimal disruption to the operation.