Goods-to-Person Systems

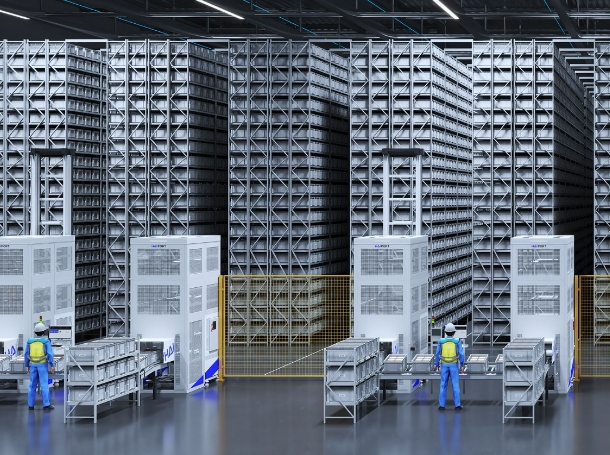

Hai Robotics' Goods-to-Person systems are automated storage and retrieval solutions designed to improve warehouse efficiency, accuracy, flexibility and scalability. By delivering goods directly to an operator or picking station, the GTP system minimizes human involvement in the order picking process, increasing productivity and safety while reducing labor costs and issues.

At MMCI Automation, our experienced team can help analyze your operation and find the perfect Goods-to-Person system to fit your needs. With over 35 years of experience in warehouse automation and robotics integration, we'll work closely with you to evaluate your workflow, space constraints, and throughput requirements to design a solution that maximizes efficiency and ROI.

Benefits of Goods-to-Person Automated Storage & Retrieval Systems

- Throughput rates are multiple times higher than a fixed aisle AS/RS

- Quick access to inventory

- Scaleable design allows for inventory growth

- Speeds up inventory release, increasing efficiency

- Good when storage density is needed because of limited space

- Can help reduce damage to product

- Improves organization

Types of Automated Storage and Retrieval Systems

Unit Load AS/RS - Designed to Handle Heavy Loads

Mini Load AS/RS - Designed to Handle Lighter Loads

Pallet Shuttle AS/RS - Designed to Handle Pallet Loads

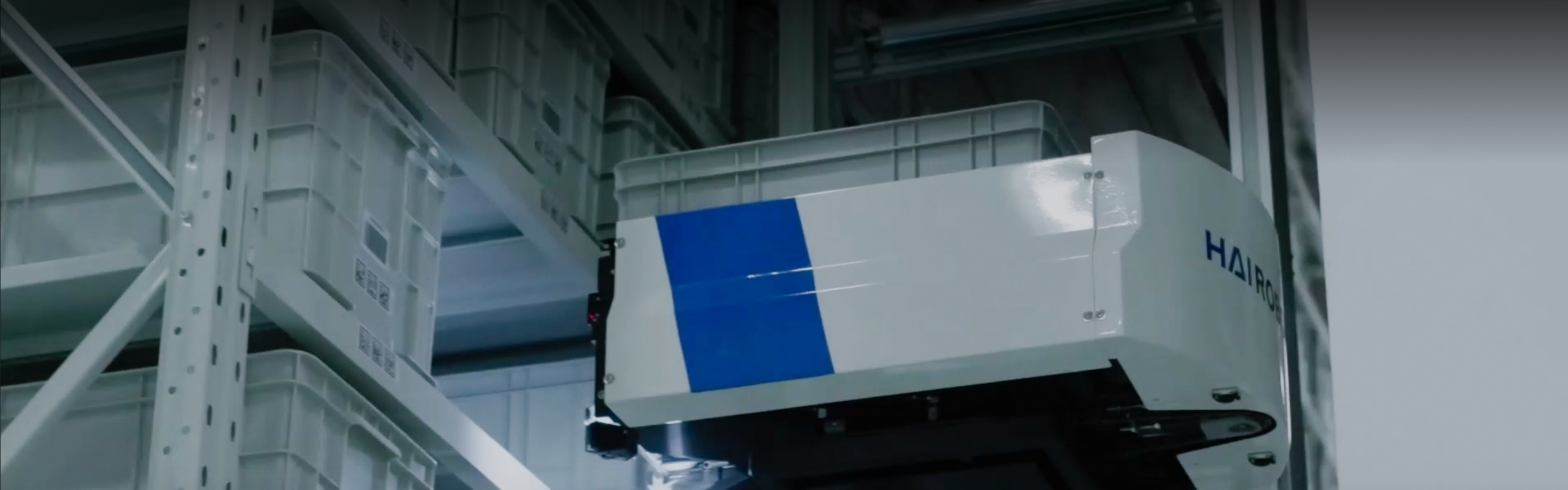

HaiPick Systems

MMCI partners with Hai Robotics to deliver cutting-edge automated storage and retrieval solutions that dramatically improve warehouse efficiency and productivity. Our experienced team will analyze your operation's unique requirements and help you determine which HaiPick system will best optimize your storage density, increase throughput, and maximize ROI.

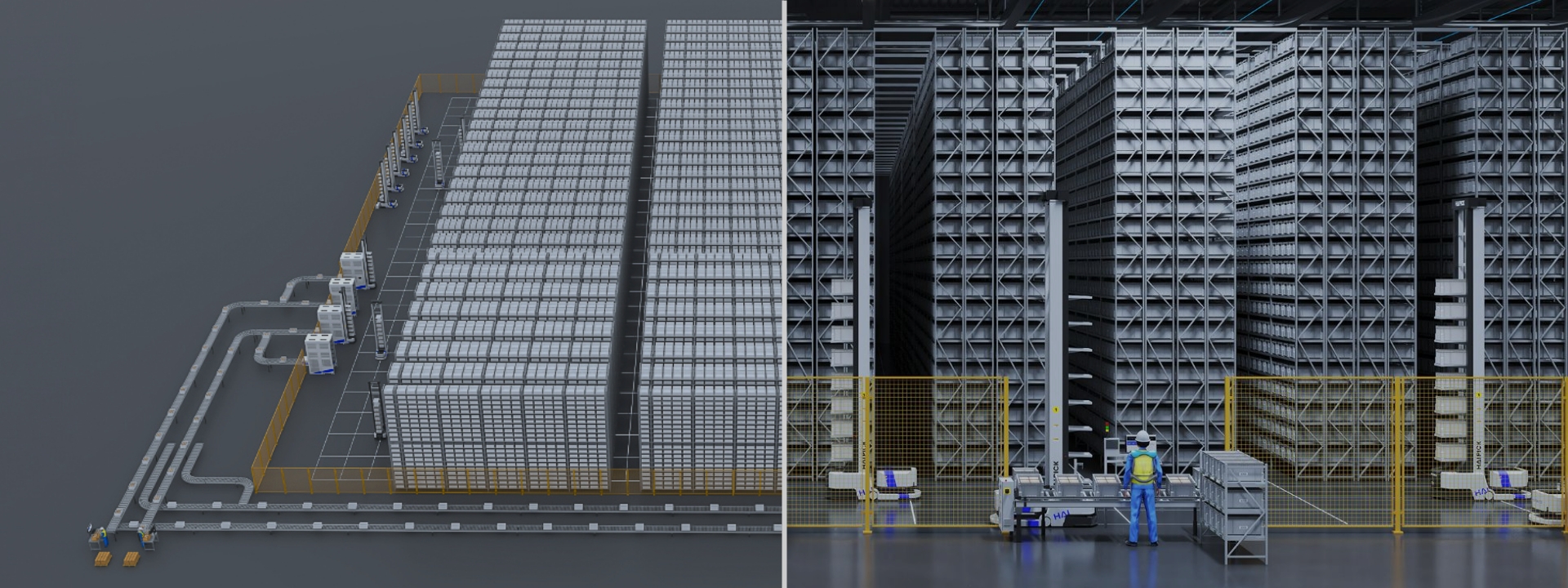

HaiPick System 1

HaiPick System 1 is our essential goods-to-person solution that offers superior flexibility and scalability to improve warehouse operational efficiency and reduce unused storage space.

HaiPick System 2

HaiPick System 2 is a tandem Autonomous Case-handling Mobile Robot (ACR) and Autonomous Mobile Robot (AMR) goods-to-person solution that offers superior versatility and compatibility to improve warehouse operational efficiency and increase storage density.

HaiPick System 3

HaiPick System 3 is an innovative goods-to-person solution that offers superior flexibility and scalability to improve warehouse operational efficiency and maximize existing storage capacity significantly.