Warehouse Control System (WCS)

Bridging Your WMS and Automation Equipment

Our Warehouse Control System (WCS) is the bridge between your WMS and automation equipment. The WCS drives material and information flow to order fulfillment technology and is often paired with a WMS/WES/ERP system. This intelligent approach determines the most efficient product flow and balances system activity by ensuring orders are released in quantities your system can handle to achieve optimal continuous processing.

Solutions for Every Application & Budget

The key to WCS software is its ability to integrate in real-time with the various material handling technologies utilized in one's operation. Our team can work with you to deploy modular software solutions that control automated solutions like conveyor systems, robotics, goods-to-person systems, etc. Our WCS can then be tailored and configured to address customer-specific requirements for efficient routing of orders.

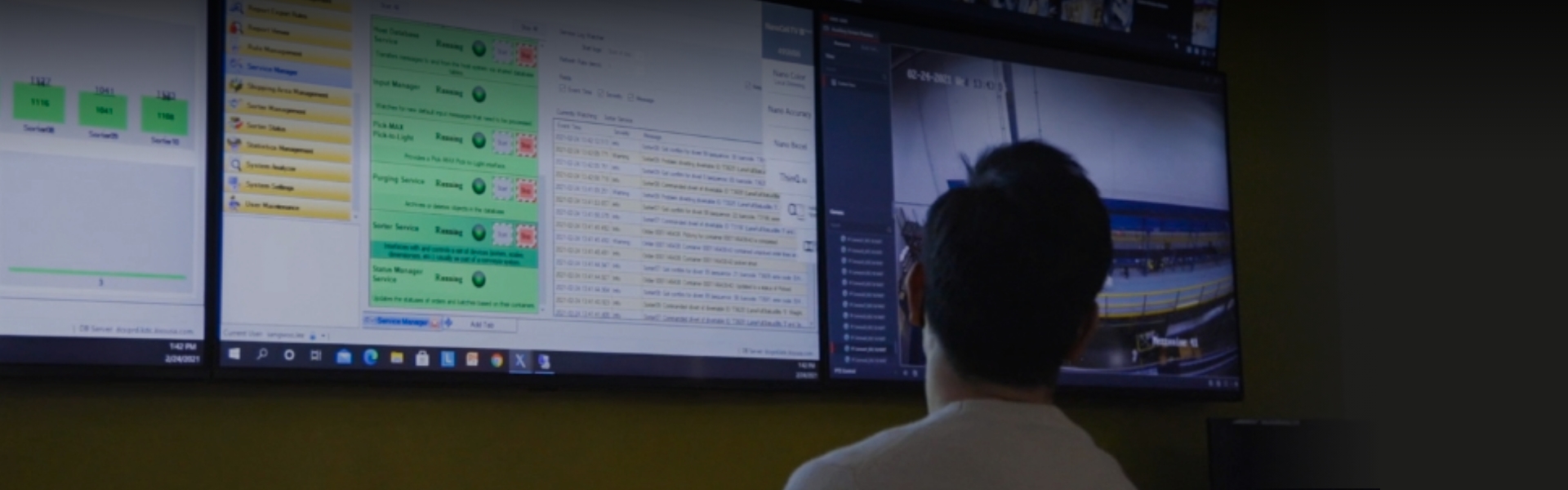

Innovative HMI

At the heart of our WCS solution is a Human Machine Interface (HMI). Intuitive HMIs are designed to provide the visibility and ease of use your operators and maintenance staff require to effectively operate your automation solutions.

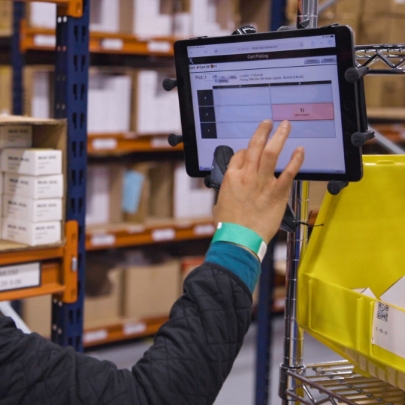

Pick System Integration

Our WCS has integrated a large variety of automated picking systems including:

Other System Integration

In addition to automated picking systems, the DCX Software Suite can be used to integrate a wide variety of automation equipment.

Technologies

- Lower-level conveyor controls systems (PLC)

- Auto-Induction (box builders)

- 1D and 2D Scanners

- Scan Tunnels

- RFID Readers

- Print & Apply Machines

- Weigh-in-motion Scales

- Packing or Void Fill Machines

- Sortation Systems

- Shipping Systems

- Palletizing Robots