Warehouse Execution System (WES)

Our Warehouse Execution System (WES) solution is capable of directing all of the process you would typically utilize in a Distribution Center. It organizes and optimizes in real-time your activity flow and aligns all warehouse resources to ensure you are getting the most out of your operation.

A Wholistic, Real-time Approach

We have combined our WMS and WCS software to provide a wholistic approach to your warehouse or distribution operation. This Real-time visibility of your employees and material handling technology allows you to balance workloads in the most efficient way possible.

Organize Daily Activities

Order Management, Cubing, Waving, and Workload Balancing modules provide the tools needed to allow operations to organize and plan daily activities.

Visibility to Track Progress

Customizable rules make automating processes easy, requiring minimal input from operations and providing users with the flexibility to configure the system to match one's normal operating procedures - with visibility to track progress throughout the day.

Order Management

The Order Management module is the primary system managers will use to check the progress of orders through the system. It provides easy-to-use charts that display every order, container and wave status used in the system.

Used in conjunction with the our Order Allocation Module, this allows operations managers to control which business rules to it Allocation Service.

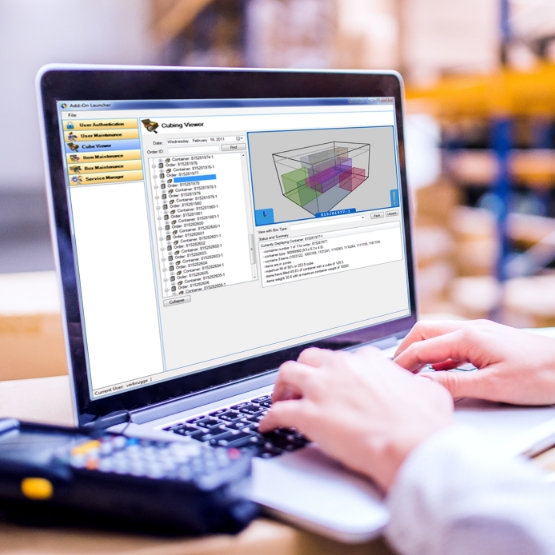

Cubing

As one of the most popular modules within the DCX Software Suite, the Cubing module does more than just perform volume calculations. It provides full rotation collision detection on each item as well as taking into consideration nestable items and multiples for handling odd shaped items - viewable with a full 3D Graphics Add-On that allows the operators to see exactly what is going on.

More advanced options include the calculation of DIM weights to improve shipping costs or the assignment of pick zones that reduce the number of divert points a container needs to be routed.

Wave & Waveless Order Management

Once orders have been allocated and cubed, the Wave Management module can group orders together to achieve the most efficient picking schedules possible. Users can view the current and pending waves, configure rules for how the waving occurs and manually create a wave from any cubed orders in the order pool.

This extremely flexible approach allows our system to run in full automatic mode, reducing the need for operators to have to manually create waves, even though they still can if needed.

Workload Balancing

Once waves have been created, the system will analyze the available waves and the current workload on the system to release waves in an organized manner - so as to not overwhelm any given picking location.

Operations managers have quick full control on a per Master Wave and per Pick Area basis of determining what should be released at any given time. They also have the granular control of releasing just a specific wave to override the automated release if so desired.