Robotic Palletizing Systems

Our mission is to provide turnkey robotic palletizing systems – from design and installation to ongoing support and maintenance – that increase product throughput, maximize plant efficiency and improve quality.

Our Technology Center

Whether your interest lies in one of our Quick-Ship Palletizers or a completely customized robotic solution, we design, build and test all systems in our Robotics and Automation Technology Center in St. Louis, Missouri. Here, we can run simulations with your product and perform Factory Acceptance Tests before deploying.

Specialists in Automated Palletizing Systems

With decades of experience and countless installations, our team has completely streamlined the design, assembly, programming, and installation of robotic palletizers.

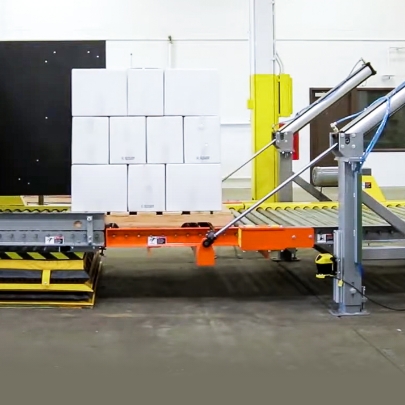

"Quick-Ship" Robotic

Palletizers

Cost-effective, pre-engineered robotic palletizers that ship quickly, install easily and run efficiently.

Purchase prices start at $175,000 or choose our SmartLease program.

"Quick-Ship" Cobot

Palletizers

Safe, easy-to-integrate collaborative robots that are revolutionizing the industry.

In stock with prices starting at $100,000 or choose our SmartLease program.

Customized Robotic Palletizing

Systems

Customized robotic palletizing solutions for atypical products, increased automation or other special applications.

Pricing varies, but SmartLease options are available.

Other Robotic Solutions

While our specialty lies in automated palletizing, we will often develop robotic solutions to perform additional upstream tasks like case packing or order picking.

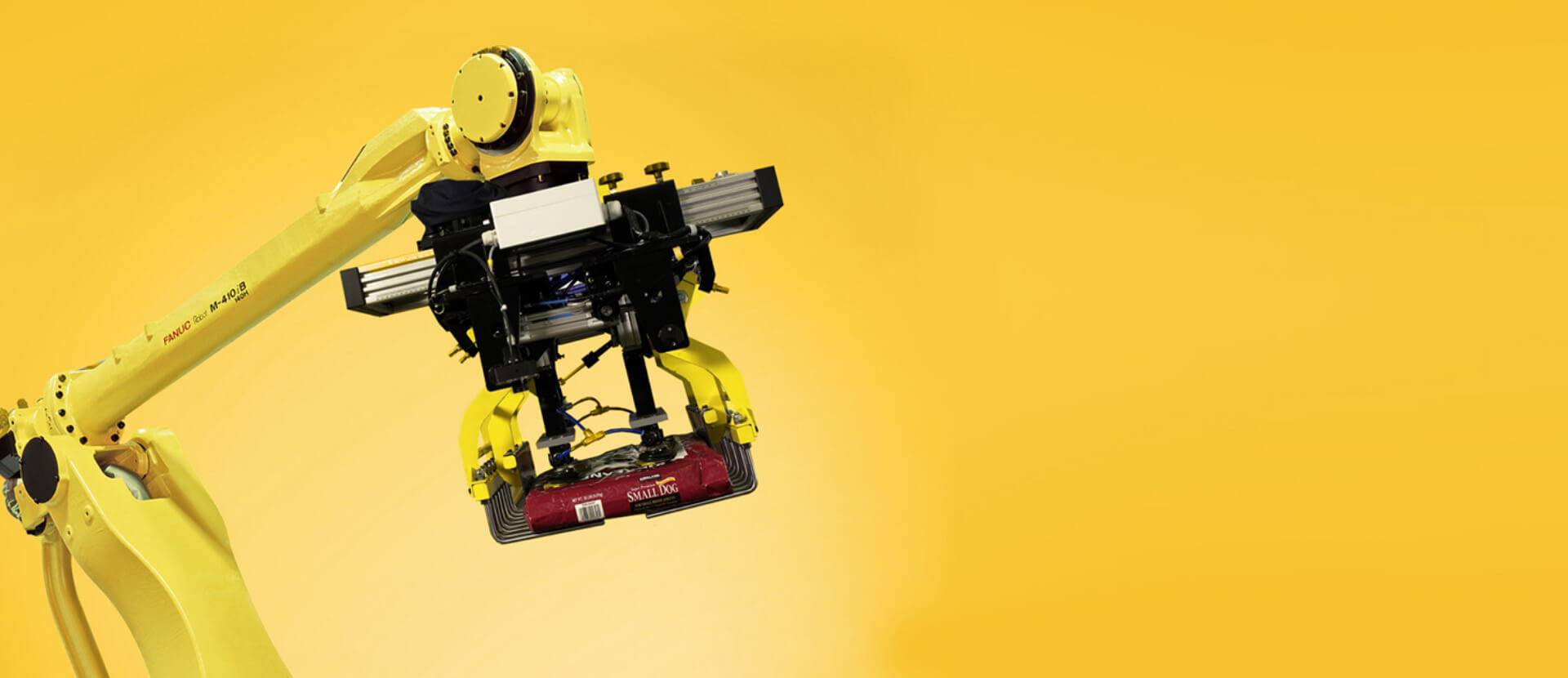

Industry Leading Technology

We are an Authorized Systems Integrator for FANUC robotic palletizers and utilize other industry leading technology from Allen Bradley, Troax and more.

Very Satisfied Customers

We work with many of the leading companies in the world across a variety of industries to deliver material handling solutions worthy of global leaders.