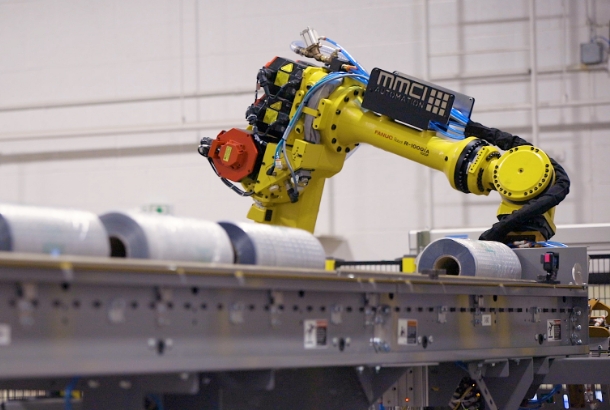

Robotic Roll Handling & Palletizing

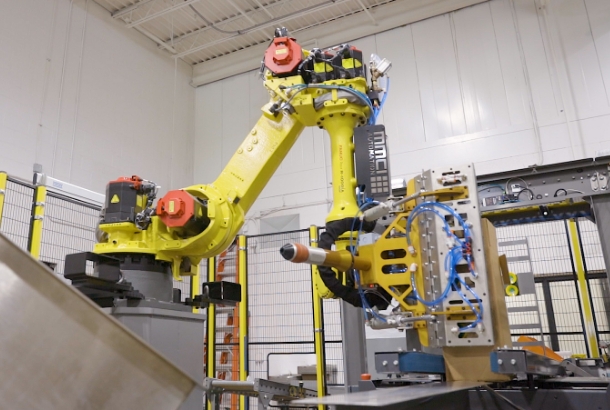

Palletizing heavy rolls represents one of the more significant engineering challenges that we face at MMCI Robotics. The robotic palletizer arms typically require highly customized end-of-arm-tooling and extensive controls work to maximize productivity, flexibility and more.

Key Benefits

Working with one of the leading manufacturers of packing supplies in the world, we have developed a system for case packing and palletizing rolls that is not only safer and more cost-effective, but it can also improve quality, productivity and more.

Safer

Perhaps the greatest benefit of these systems is that they eliminate the strenuous processes required to manually pack and palletize heavy rolls.

More Cost-Effective

Not only does the system eliminate labor, but integrated accumulation conveyors and flexible EOAT minimize downtime and eliminate bottlenecks to increase productivity.

Better Quality

The utilization of an ID Gripper on the EOAT minimizes scuffing of the product and allows each roll to be gently set into the box - minimizing carton damage.

Smarter

Strategically mounted scanners capture information laser-etched onto cores so that each roll can be tracked throughout its entire lifecycle.

Flexible

From the modified inbound conveyors to the innovative end-of-arm-tooling, the system can pack and palletize rolls in a wide variety of lengths, diameters and weights.

Comprehensive

Our robotic roll handling processes can be modified to pack the rolls into cases or place the rolls directly onto a pallet with some minor engineering customization.

A Case in Point

See how we helped a leading manufacturer of packaging film pick, pack and palletize more efficiently.