Pallet Picking & Dispensing Options

MMCI offers a number of standard methods for placing, picking or automatically dispensing pallets into the robotic cell and placing them in the correct position. Our engineers can review your line speeds, space, flexibility requirements and overall budget to determine the best solution for your application.

Option 1: Manual Pallet Placement

The least automated, but often least expensive and smallest footprint options include manually feeding pallets into the cell or on infeed conveyor one pallet at a time.

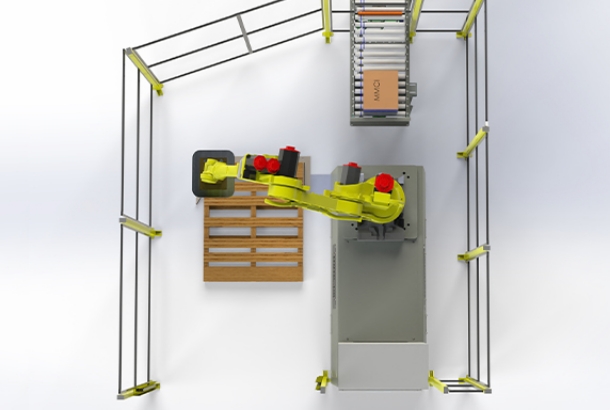

1 Pallet Location

With this configuration, the robotic palletizing arm is stopped once the pallet is full so that it can be removed and replaced with an empty pallet in a pre-determined spot.

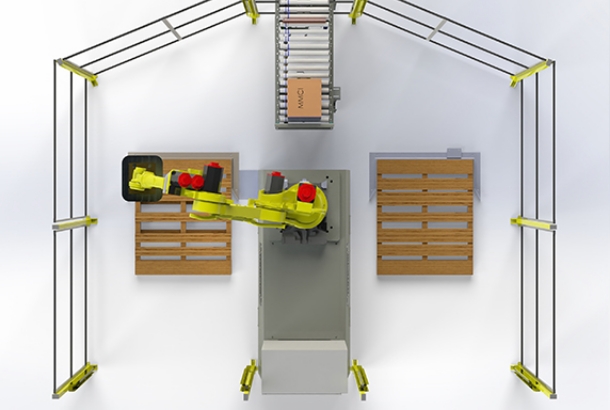

2 Pallet Locations

With this configuration, the robotic arm switches to loading a second pallet in the cell while the first is removed and replaced manually.

Manual Hopper/Automatic Discharge

In this semi-automated configuration, the cell features a manually loaded pallet hopper that can be loaded with up to X pallets and an automatic pallet discharge conveyor that can discharge a full pallet. The robot will then automatically place a new empty pallet from the hopper to the build zone and continue palletizing.

Option 2: Robotic Pallet Picking

To achieve a higher level of automation, cells can be outfitted with a pallet magazine that holds a number of empty pallets for automatic picking and placement by the robot.

How It Works

A pallet magazine designed to store multiple pallets is placed inside the cell beyond a safety fence or light curtain. The speed in which it needs to be refilled is determined by the speed of the line, but the goal is to limit the manual activity associated with bringing pallets to the cell.

To move the pallets from the magazine to the palletizing area, we integrate a pallet handling attachment to the end-of-arm-tooling or use our innovative pallet-swap tool shown below.

Automated Tool Swap

For certain applications, MMCI engineers have developed an innovative system in which our standard end-of-arm-tooling can secure a pallet-grabbing device, select the pallet from the magazine and place it in the correct position. See it in action.

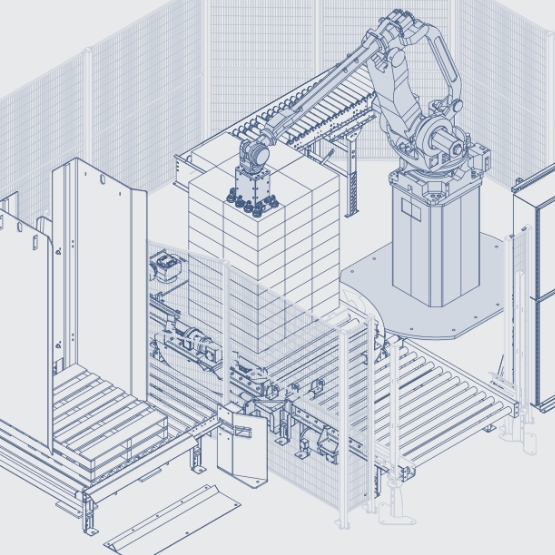

Option 3: Automated Pallet Dispensing

When the highest level of speed and automation are required, the integration of a high speed automated pallet dispenser is often the best option. At MMCI Robotics, we have worked to develop our own models to integrate seamlessly with our pre-engineered cells.

How It Works

We typically place one of our automated pallet dispenser near the edge of the palletizer cell, close to the palletizing location.

Here, operators can fill the pallet hopper and the dispenser will automatically transfer the pallets into the cell through a powered conveyor.

TH FD-1500 & FD-2000

MMCI's FD-1500 and FD-2000 automated pallet dispensers offer excellent flexibility, operate more reliably and lower the overall cost of the pallet handling process.