Zippy Ice

The Client & Objective

As a supplier of ice to over 1,000 convenience stores, restaurants and grocery stores in North Carolina, Zippy Ice knew it had to expand its palletizing operation in order to grow its business. The question was whether to hire and train more people for this unwanted job of stacking bags of ice or invest in automation.

The Solution

After evaluating Zippy's operation, space and current palletizing process, the team at MMCI Automation recommended its IcePal 200 robotic ice bag palletizer. The small-footprint palletizer was outfitted with innovative end-of-arm-tooling that could efficiently stack many different sized bags and featured an automated pallet conveyor that could accommodate multiple sizes and styles of pallets.

See the Entire Line of IcePal Palletizers

IcePal palletizers come in three standard models. All models utilize the same highly reliable FANUC robotic arm but include enhancements for pallet conveying, dispensing and wrapping.

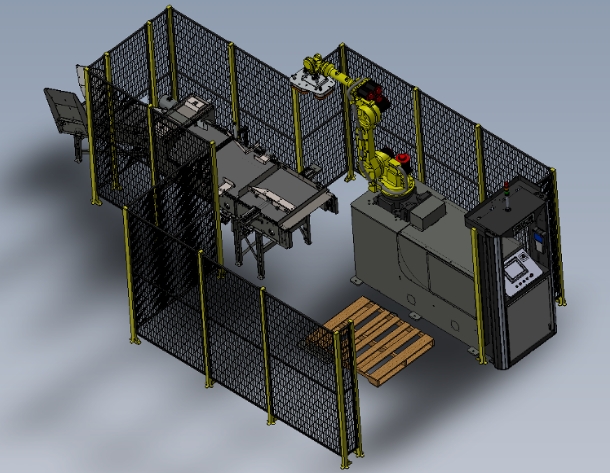

IcePal 100Compact, Cost-Effective Automation

Single Pallet: Perfect for operations seeking to automate with a smaller footprint.

Flexible Layouts: Offers the same adaptability as the IcePal 200 in a more compact form.

Small Footprint: Fits into tighter spaces without sacrificing performance.

Low Entry Cost: Provides an affordable entry point into automation.

High Capacity: Matches the IcePal 200 with the capability to handle 35 Bags per minute.

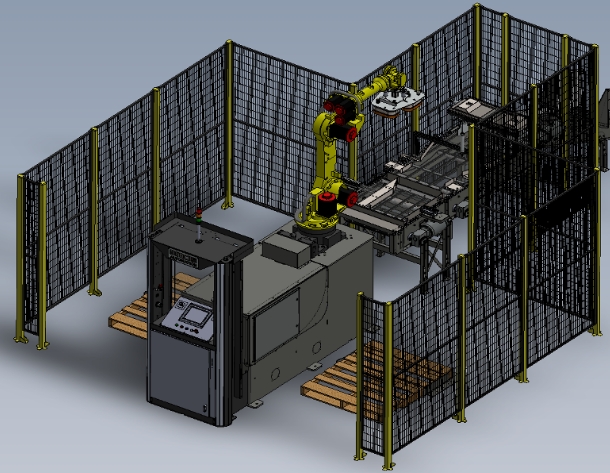

IcePal 200The Powerhouse of Efficiency

Double Pallets: Maximizes productivity by handling two pallets simultaneously.

Flexible Layouts: Adapts to your space, allowing for a variety of configuration options.

High Capacity: Powers through your demands with the ability to process 35 bags per minute.

Expandable: Scales with your business, ensuring that increased demand is never a problem.

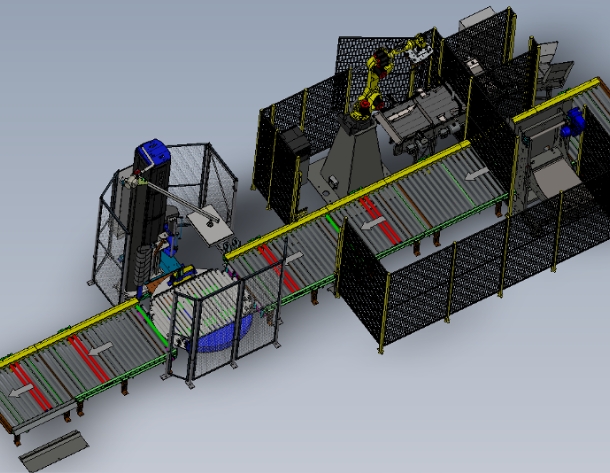

IcePal 300The Pinnacle of Ice Bag Palletizing Efficiency

Most advanced model in our line of IcePal palletizers, designed to meet the high demands of ice bag packaging operations.

Fully Automated System: Streamlines the palletizing process, significantly reducing manual labor and associated costs.

Stretch Wrapper Integration: Offers an optional stretch wrap feature, providing a complete end-of-line solution that ensures secure and stable pallets ready for transport.